Shifting Foundations: Overcoming Differential Settlement in Solar Installations

Shifting ground underneath a utility-scale solar site can damage trackers and equipment, leading to costly repairs or even complete demolition of a project. One of the most common ways a foundation can change post-installation is through a process called differential settlement.

This article will explore differential settlement in detail, and provide ways to overcome the process for a utility-scale solar installation. With the right equipment and action plan, a solar farm can withstand surface changes from differential settlement and stay functioning for decades.

What is Differential Settlement?

Differential settlement is a natural process where one area of soil shifts and changes relative to surrounding areas, causing an uneven surface. When this process occurs under the foundation of a structure like a utility-scale solar farm tracker, the results can be devastating.Most solar projects require a flat area of land to build on — which is precisely why mass grading is so prominent in the industry — but unfortunately, differential settlement can alter the ground even after an installation, leading to potentially severe equipment damage.

What Causes Differential Settlement?

Differential settlement can happen at any time for a number of reasons. Because it’s so unpredictable, it can be hard to plan for, which is why it’s important to have an action strategy ready to overcome the issue. Here are the most common causes of differential settlement.

Soil Composition

Differential settlement involves shifting soil, so it makes sense that a leading cause of the process is the state of the soil itself. If one area of soil under a solar project has a different composition than other parts, it can result in an uneven surface. For example, soil that contains sand will settle deeper than clay.

Moisture

The soil’s moisture levels can also lead to differential settlement. If the soil has too much or too little moisture, it will settle deeper than soil with a more moderate moisture level.

Soil Liquefaction

Excessive shaking and vibration, often from earthquakes, can reduce the strength and firmness of soil. This phenomenon is called soil liquefaction, and it can lead to significant instances of differential settlement.

Underground Cavities (Karst)

Differential settlement can also occur due to internal erosion — also called karst — from underground cavities like mines or sewer pipes. Over time, these cavities can loosen and weaken the soil above.

How Can You Overcome Differential Settlement in Solar Installations?

You can’t avoid differential settlement itself, but you can implement measures to keep structures from bending, jamming up, and breaking because of the changing surface.

In terms of solar installations, the best possible course of action is to use trackers that can withstand a shifting foundation without incurring damage. This is exactly what the Nevados All Terrain Tracker® (ATT®) offers.

Continuous vs. Non-Continuous Torque Tubes

One of the reasons why the ATT® can withstand differential settlement better than other solar trackers is that it’s built with non-continuous torque tubes. Typically, a 3-string row is comprised of 12-14 individual torque tubes. Most traditional solar trackers have a continuous straight ~100 meter long torque tube configuration, which can’t adjust to a changing surface.

When differential settlement occurs underneath a tracker with continuous torque tubes, the components bend, jam up, and parts break as the surface becomes uneven. Foundation movement of only a few inches can cause permanent damage to a continuous torque tube tracker. Thanks to proprietary Nevados articulating bearings foundation movement of 12 inches or more can be easily accommodated without any damage.

Articulating Bearings

The ATT® offers two levels of bearings that can be easily swapped out to adapt to changes in slope. The first kind of bearing is the standard straight-through bearing, which allows for a slope change of up to +/- 4.4% between each post. The second is articulating, which accommodates up to +/- 26% slope changes. This means that multiple feet of relative movement of adjacent piles can be easily managed by the Nevados ATT®.

On either side of both bearings are the cradles in which the torque tubes rest. If differential settlement occurs, the cradles’ side walls, back walls, and clamps flex to accommodate angle changes; the shaft does not contribute to flexure. Each cradle can accommodate +/- 1.25° of angle change.

When the angle exceeds the tolerance window of one bearing, all it takes is a quick swap for the next most capable bearing to regain the full lifespan of the tracker. In the meantime, your current bearing will still continue to function as expected. There is practically no limit to the amount of foundation movement the Nevados ATT® can handle. For most solar trackers on the market, almost any minimal foundation movement will result in damage and repair that requires complete dismantling of an entire row. With the ATT® swapping a bearing is an easy one-person job.

Overcoming Differential Settlement With The ATT®

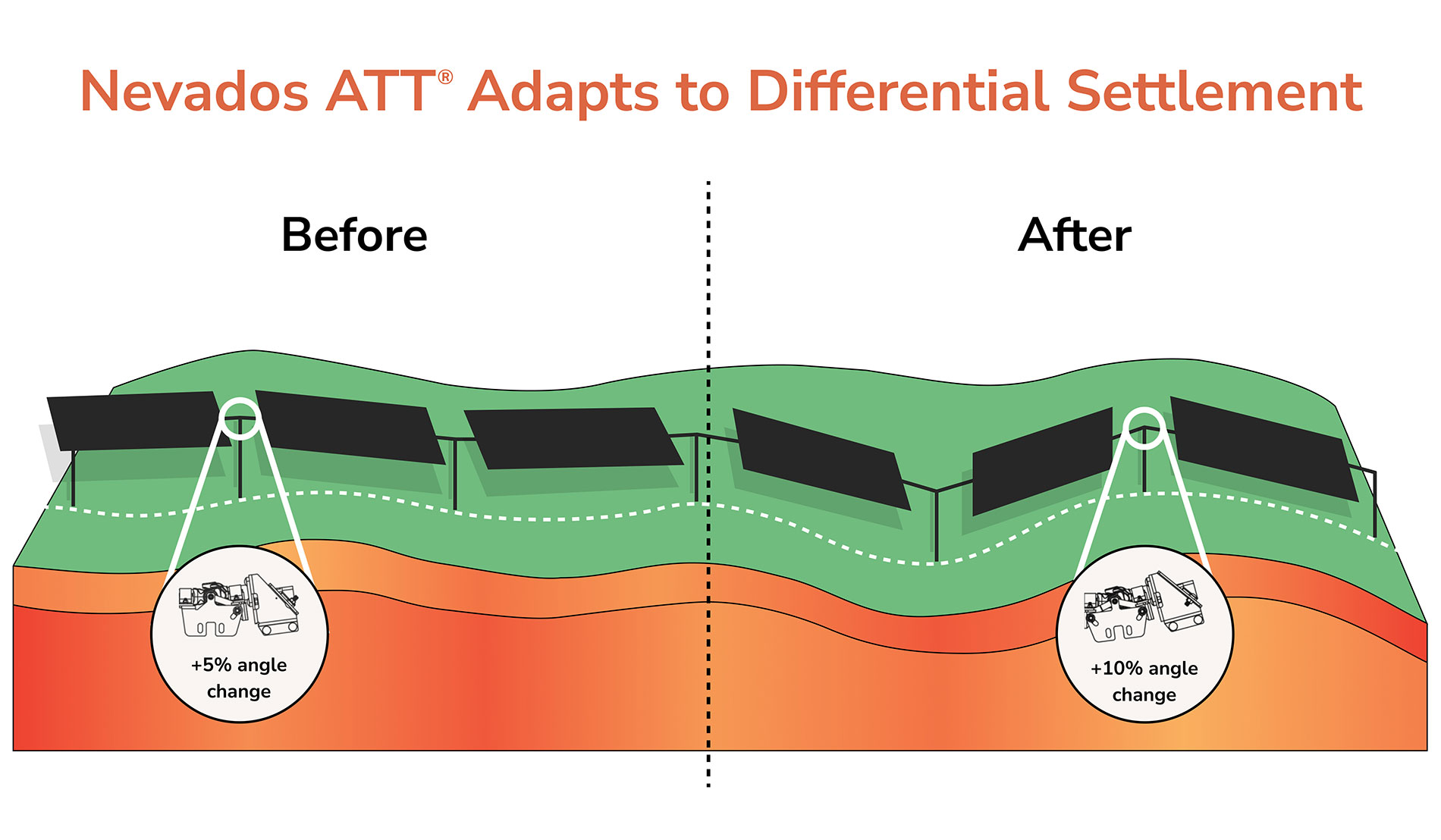

Because the ATT® is built with non-continuous torque tubes and articulating bearings, the tracker can tolerate extreme cases of differential settlement without becoming damaged or losing any functionality. This is demonstrated in the diagram below, which shows the ATT® seamlessly adapting to +5 and +10% angle changes due to differential settlement.

What To Do When Differential Settlement Occurs

It’s important to have a plan of action if differential settlement occurs at the site of your solar project. Here are some ways to overcome the issue before it causes any serious damage:

Do a Drone Flyover

Starting with a drone flyover to map the top of pile locations after construction is critical to establish a baseline. If a settlement event occurs you can simply fly the site again to map the new top of pile locations to calculate the angle change between piles. From there, you can zero in on problem areas and make the necessary repairs or replacements.

Determine New Angle Changes

When differential settlement does occur on your project site, you can determine the level of movement by assessing angle changes. The bigger the change, the more extreme settlement has occurred and the more likelihood of potential damage on continuous torque tube trackers. With the ATT®, you can simply replace the bearings to account for the new angle.

Make Necessary Replacements

If differential settlement causes an angle that’s too steep for your tracker, it’s necessary to replace the bearings to account for the changing surface. For the ATT®, switching out bearings is easy, allowing your solar project to overcome even extreme cases of differential settlement.

The Nevados All Terrain Tracker® in Action

The All Terrain Tracker is already helping solar manufacturers and project leaders keep their utility-scale projects safe from differential settlement. Take it from Dave Williams, CEO of Valta Energy:“The risk of differential settlement has emerged as solar project siting has become more challenging. The All Terrain Tracker® has been a welcome improvement over other trackers we’ve used because it can withstand substantial soil movement without equipment damage. Best of all, when we do have to replace parts, the process is extremely simple with the ATT®. With Nevados differential settlement is no longer high risk.”

Safeguard Your Solar Project With The ATT®

While it may not be possible to prevent differential settlement, the All Terrain Tracker® is capable of safeguarding your solar project and keeping equipment free of damage. With a non-continuous torque tube design and articulating bearings, the ATT® can not only be built on uneven terrain, it can withstand changing surfaces and soil movement long after installation.

To learn more about the ATT® and how you can implement it for your next large-scale solar project, reach out to our team at Nevados today.