The editorial team at Solar Power World had the great opportunity to mingle with 27,000 friends at this year’s RE+ tradeshow in Anaheim, California. Besides stopping by happy hours and food truck lunches, we filled our time visiting as many booths as possible to check out the newest products on display.

The solar and storage industries have evolved quite a bit since the last major tradeshow in 2019. Solar panels are bigger, trackers are more accommodating and inverters are smarter. There have been many impressive developments in the last few years to make solar and storage easier to deploy. We tried our best to pick a few of our favorites from 2022.

Be sure to visit our online database for an even more extensive list of the top products from 2022.

Truly modular designs make energy storage more powerful, easier to install

As seen in Canadian Solar’s EP Cube

SPW editors have only chosen a battery once in the five previous years of compiling our favorite products. That’s because batteries used in energy storage systems, especially in the residential market, are mostly just gray boxes with nothing exciting on display. The highest capacity available was usually reached by Tesla with its 13.5-kWh Powerwall, but its 5-kW inverter often leads most households to default to two or more units to meet power needs. Tesla’s nickel manganese cobalt (NMC) chemistry works great, but many safety-conscious installers and homeowners are demanding more lithium-iron phosphate (LFP) brands that can easily be installed outdoors.

SPW editors have only chosen a battery once in the five previous years of compiling our favorite products. That’s because batteries used in energy storage systems, especially in the residential market, are mostly just gray boxes with nothing exciting on display. The highest capacity available was usually reached by Tesla with its 13.5-kWh Powerwall, but its 5-kW inverter often leads most households to default to two or more units to meet power needs. Tesla’s nickel manganese cobalt (NMC) chemistry works great, but many safety-conscious installers and homeowners are demanding more lithium-iron phosphate (LFP) brands that can easily be installed outdoors.

Enter the truly customizable and modular EP Cube energy storage system from Canadian Solar. The easy-to-expand single unit has a 7.6-kW inverter on top, stackable battery modules in the middle and all the wires condensed in the bottom plate. Each battery module averages about 3.3 kWh, making expandable capacity more affordable when someone needs a bit more than 13.5 kWh but not quite 27 kWh. The LFP-based system can be floor- or wall-mounted, and the entire unit is NEMA 4X rated — the highest outdoor rating we’ve seen for any ESS.

Each 3.3-kWh battery module in the EP Cube weighs around 70 lbs, which is much easier to install than the Powerwall’s 250-lb system. This means fewer installer hands needed to get batteries hooked up and commissioned. It’s still a gray box — but the EP Cube’s metallic tint makes this ESS attractive enough to display outside anyone’s home.

Solar permitting and design software helps installers expand to new regions

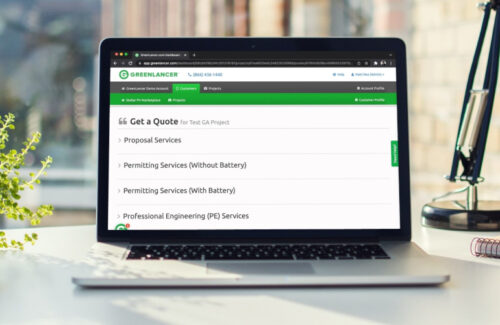

As seen in GreenLancer’s permit design and engineering marketplace

One stubborn roadblock for solar installers looking to expand into new geographic areas is the amount of variation in permitting and design requirements in local building departments. It can take time and resources to learn each department’s intricacies — with inevitable delays if there are errors on permitting documents.

One stubborn roadblock for solar installers looking to expand into new geographic areas is the amount of variation in permitting and design requirements in local building departments. It can take time and resources to learn each department’s intricacies — with inevitable delays if there are errors on permitting documents.

Solar software companies continuously attempt to reduce these soft costs that hurt the bottom line of solar installers big and small. One provider has created a marketplace to connect solar companies with design and engineering firms across the country that already have experience with the nuances of local building departments.

“Having design expertise in all of those areas helps the installer to basically jump into it without having to have extensive understanding of that side of it,” said Matt Rea, VP of revenue operations at GreenLancer.

GreenLancer is a platform that allows installers to pay for permit drawings, interconnection applications and other documents from a network of design and engineering firms at prices standardized by the software company. GreenLancer’s in-house support team assists throughout the process, serving as the facilitator between contractor and design firm and solving any issues that arise in the process.

Some contractors use GreenLancer as their entire design and engineering branch. Others use it as an overflow — they have an in-house design team but need some help during the busy season.

“With the ebbs and flows of the solar industry, there are certain times where they need to tap our shoulder and say, ‘Hey, we need to send you some projects.’ We’re happy to fill that gap,” Rea said.

Moving forward, GreenLancer plans to expand into field services too — not only connecting installers to design firms, but also connecting project owners with installers if they want to add batteries to an existing project or need O&M assistance.

“That is really the vision — an installer can come to us and get this design and engineering work done, but also they can look on our platform for work,” Rea said.

In this increasingly digital age, online marketplaces like GreenLancer help installers fill gaps in design and engineering and grow without adding new departments.

Innovation takes single-axis solar trackers to new terrains

As seen in Nevados Engineering’s All Terrain Tracker

One of the highest barriers to deploying single-axis solar trackers has been hilly terrain. Hiring a civil engineering service to grade land and produce a flat worksite can significantly increase the cost of a solar project. However, this was necessary to allow the driving mechanisms on solar trackers to rotate panel rows that previously could not compensate for undulating land. Now, that’s changing.

One of the highest barriers to deploying single-axis solar trackers has been hilly terrain. Hiring a civil engineering service to grade land and produce a flat worksite can significantly increase the cost of a solar project. However, this was necessary to allow the driving mechanisms on solar trackers to rotate panel rows that previously could not compensate for undulating land. Now, that’s changing.

One manufacturer building single-axis solar trackers for these environments is Nevados Engineering. The company’s All Terrain Tracker (ATT) has a built-in slope tolerance up to 37% overall and can work with up to 26% slope change at each foundation. The key feature making this possible is an articulating bearing that installs atop each foundation, letting each bay of panels install at different slopes, all while maintaining panel row rotation.

The Nevados solution reduces grading costs for large-scale solar installations and opens the possibility of single-axis tracking in hillier regions that have previously been confined to fixed-tilt racking. In addition to its slope tolerance, the ATT underwent environmental testing on uneven terrain and is rated to perform in up to 80-mph winds, but will stow at 45 mph. Its row controls are wireless and self-powered. ATT can safely handle up to 50 psf snow loads, and the system has a 10-year extendable structural warranty and a five-year warranty on its drive and controls.

With new products like the ATT, single-axis solar trackers can continue to adapt to new topographies and grow in structural strength.

Steel frames and supports make solar panels even stronger, greener

As seen in Risen Energy’s Titan and First Solar’s Series 7

Aluminum has treated the solar industry well. Its light weight and corrosion resistance has made it the dominant material choice for solar panel frames and accessory installation products. But in an era where people are paying closer attention to the carbon footprint of all materials, more sustainable framing and support options are gaining traction.

Steel is the first material to make some inroads. Risen Energy has introduced steel frame options for its Titan crystalline silicon solar panel line, and First Solar plans to use steel back rails on its new Series 7 thin-film modules. Both companies cite the smaller carbon footprint of steel as a primary reason for switching from aluminum. According to Risen Energy, producing one tonne of aluminum exerts 11.2 tonnes of CO2 vs. only 1.8 tonnes of CO2 per one tonne of steel. And switching to steel affects the end-product very little — a steel-framed Titan panel is only 3 lbs heavier than an aluminum-framed model.

Solar panels using steel rather than aluminum get the added benefit of strength, which comes in handy on larger solar panels entering the utility-scale market. First Solar’s Series 7 module is longer and has a larger surface area than the Series 6 module, so the steel back support rails provide more structural support for the frameless Series 7 solar panel. First Solar is also tapping into the local steel industry for an even smaller carbon footprint, and all of its new U.S. manufacturing plants will be entirely dedicated to the Series 7 module with no aluminum parts.

With the cost of the solar-generating portion of panels decreasing, frames and supports become the biggest cost on a finished solar module. Aluminum is on average 2.6-times more expensive than cold-rolled steel on the global markets, so cutting this big-ticket item out will make solar panels cheaper — and greener.

Inverters offer entry-level backup options for solar customers

As seen in SMA America’s updated Sunny Boy Smart Energy inverter

Energy storage is becoming more accessible thanks to regional and federal incentives, but it’s still not economically viable for all homeowners. New inverters give solar-only homeowners some benefits of backup energy with the ability to easily add a battery later on.

Energy storage is becoming more accessible thanks to regional and federal incentives, but it’s still not economically viable for all homeowners. New inverters give solar-only homeowners some benefits of backup energy with the ability to easily add a battery later on.

SMA America has included a “Secure Power Supply” feature in its Sunny Boy inverters since 2015. These inverters include terminals for installers to add either a quad or dual electrical outlet underneath the unit or by the main critical load in the home. In the event of a daytime power outage, homeowners can plug their critical load, like a refrigerator, into that solar backup outlet and keep it running on up to 2 kW of power until the electric grid is fixed.

Now, the company is changing names and adding new options to the system in its updated Sunny Boy Smart Energy inverters, which are expected to start shipping in mid-2023. That entry-level solar backup version is now called “Backup Secure,” but the company is now offering two more robust backup options. The first is “Backup Select,” which requires installation of an additional SMA accessory but can double the power capacity to almost 4 kW of backup energy without a battery when the sun is out. Backup Select inverters come with a dedicated electric panel with up to six breakers prewired, so when the power goes out during the day, those circuits are automatically backed up.

The most advanced iteration of the Sunny Boy inverter is “SMA Backup Home,” which is a full backup solution paired with a battery to provide auxiliary power in the day or night. This system can tie into the main electric panel of the home to back up numerous circuits.

SMA’s tiered solutions are all based in its flagship Sunny Boy inverter, so homeowners have flexibility as demand, electric costs and incentives change over time.

“For a low-cost entry, they can have automatic backup during the day using clean energy, and if a year or two later their utility starts to offer incentives for adding storage, they can easily add a battery to that same platform without changing anything,” said Rob Lamendola, product manager for home solutions at SMA America.

Future-proofing solar arrays is getting easier as hybrid inverters with built-in backup options become the norm.

Deployable pulley system turns ladders into solar panel lifts

As seen in Solmetric’s Module Lift

Solar panels continue to increase efficiency, but along with that leap in generation comes an increase in size and weight. Manufacturers producing complementary technologies must adapt to these new dimensions and outputs. For one, racking and mounts must be fabricated with greater consideration to keep these large-format panels in place. But the ones feeling the greatest impact of heavier panels are solar installers themselves — especially contractors working on rooftops, hauling modules up ladders.

Solar panels continue to increase efficiency, but along with that leap in generation comes an increase in size and weight. Manufacturers producing complementary technologies must adapt to these new dimensions and outputs. For one, racking and mounts must be fabricated with greater consideration to keep these large-format panels in place. But the ones feeling the greatest impact of heavier panels are solar installers themselves — especially contractors working on rooftops, hauling modules up ladders.

Solmetric is known for producing shade analysis and other field solar array testing equipment, and now the company has developed a pulley system that attaches to ladders to bring panels to the roof. The Module Lift is designed to work with fiberglass ladders, a common and necessary tool for residential rooftop solar installation. A pulley is attached to the top of the ladder and a patented hook latches onto the solar panel’s frame. The operator pulls the rope and hoists the panel up the ladder along a ramp that prevents the panel from colliding with anything along the way. A brake stops any backward motion as the panel is lifted to the roof.

For solar installers working at heights, there are safety measures to mitigate worksite accidents, like wearing protective equipment and anchoring to the roof surface to prevent falls. But there are always risks involved with climbing a ladder. Solar panels have never been light, but they can now weigh upwards of 50 lbs. A tool like Module Lift reduces the risk of working at heights with heavy materials and gives residential module makers a bit more freedom to continue to increase the size of panels.