PROJECT

IRIS - CONSTRUCTION

CLIENT

Primoris Renewable Energy

LOCATION

Franklinton, LA

PROJECT SIZE

13MW

MODULE

First Solar Series 6

RACKING

Nevados All Terrain Tracker

PROJECT

DESCRIPTION

D. E. Shaw Renewable Investments decided to increase the site capacity of a project in Louisiana but needed the economics of the project to make sense. 70MW of a 2P tracker had already been selected for the site, and the only remaining land to increase capacity contained challenging terrain and tight boundaries. The project was located in hurricane territory, so a robust, but flexible system was required to move forward with developing on this portion of the land.

NEVADOS

VALUE

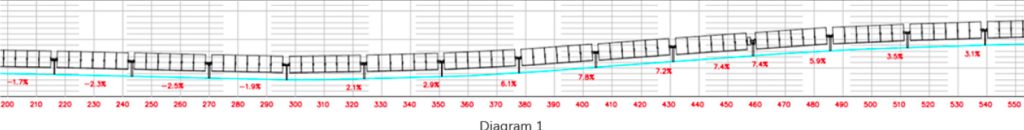

Nevados was selected to increase capacity by using land not accessible by traditional trackers without significant grading. A comparative grading profile of the site was created, showing as great as a 7.8% slope change at a single foundation (Diagram 1).

D. E. Shaw Renewable Investments decided to increase the site capacity of a project in Louisiana but needed the economics of the project to make sense. 70MW of a 2P tracker had already been selected for the site, and the only remaining land to increase capacity contained challenging terrain and tight boundaries. The project was located in hurricane territory, so a robust, but flexible system was required to move forward with developing on this portion of the land.

As one of the nation’s largest independent solar power produced (IPPs), DESRI understands the impact that severe weather can have on solar project operations. Our Nevados trackers experienced a direct hit from a Cat. 3 hurricane and performed very well; they did not sustain any structural failure and were 100% available almost immediately after the storm.

CHRIS CLEVENGER

Chief Operation Officer D.E. Shaw Renewable Investments (DESRI).

With uniform foundation reveal heights, the structure was easily built at chest height using pre-assembled bearings that were simply placed on top of the piles with finger-tight bolts. As the torque tubes were installed, the bearings auto-aligned, eliminating the costly bearing alignment steps necessary for other solar trackers. This combination of labor efficiencies positively impacted the construction schedule by making up for lost time spent on other portions of the site. In addition, following completion of the site, there was no requirement to reseed the Nevados portion as vegetation grew back fully without issue.

From a design perspective, the site boundaries were particularly difficult, requiring avoidance of wetlands and the use of variable row lengths. The Nevados ATT effectively adapted to buildable areas of the site to fully maximize available capacity. Where possible, Nevados used shared row ends, sharing the north-most foundation of one row with the south-most foundation of the next. This approach reduces the quantity of foundations and associated tracker components to support in cost saving efforts.

KEY STATS

7.8%

Slope change at a single foundation

0%

No grading required

IMPROVED

Construction schedule through installation efficiencies

FIELD GALLERY